Warehouse Solutions

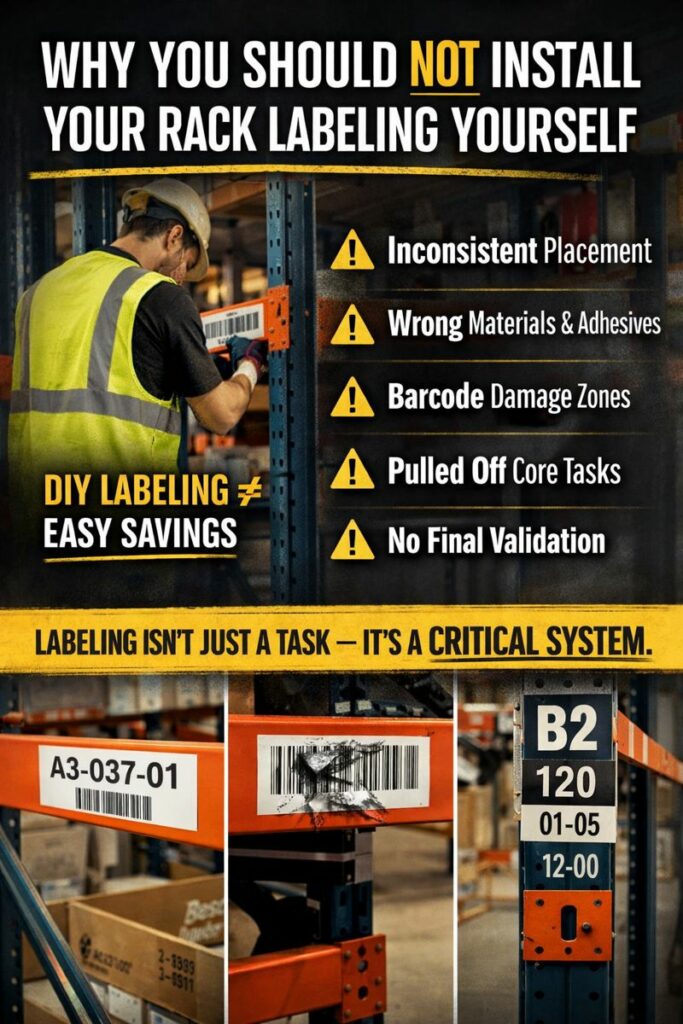

Installing Labels Is NOT a DIY Project, Here’s Why…

On paper, installing your own rack labels sounds reasonable.

You already have the racking.

You already have the team.

And surely “putting labels on beams” can’t be that hard… right?

This is one of the most expensive assumptions warehouses make.

After hundreds of warehouse labeling projects, we’ve learned a simple truth:

Rack labeling is not a printing task. It’s an operational system—and installation is where that system succeeds or fails.

The Hidden Cost of “We’ll Just Do It Ourselves”

Most self-installed rack labeling projects don’t fail immediately.

They fail quietly, over time.

It starts with:

- Slight misalignment

- Inconsistent placement

- Labels applied at different heights

- Barcodes that scan… sometimes

Then it turns into:

- Slower picking

- More mis-scans

- Operators second-guessing locations

- Supervisors answering constant questions

By the time leadership notices, the damage is already baked into daily operations.

Mistake #1: Inconsistent Placement Kills Visual Logic

Rack labels are not just identifiers. They are part of a visual hierarchy that includes:

- Totem labels

- Rack beam labels

- Floor labels

- Overhead signs

When teams self-install, placement varies by person, aisle, and shift.

One label is centered.

Another is slightly left.

Another is higher “because it felt better.”

That inconsistency forces operators to hunt instead of move.

Professional installation ensures:

- Exact placement standards

- Consistent heights and offsets

- Alignment that matches the warehouse’s visual language

Consistency is speed.

Mistake #2: Adhesives and Materials Get Chosen Wrong

Not all warehouses are the same.

Cold storage.

Dusty environments.

High humidity.

Outdoor docks.

High-impact forklift zones.

Self-installed projects often use the wrong:

- Adhesive type

- Label material

- Lamination

- Surface prep process

The result?

- Labels peeling

- Curling edges

- Smudged print

- Barcodes failing months later

By then, replacing them costs more than doing it right the first time.

Mistake #3: Barcodes Are Installed Where They Can’t Survive

This is one of the most common self-install failures.

Labels get placed:

- Where pallets rub

- Where forks strike

- Where stretch wrap tears them

- Where glare kills scan reliability

On a screen, the barcode is perfect.

On the floor, it gets destroyed.

Professional installers understand:

- Fork paths

- Traffic patterns

- Impact zones

- Real scan angles

They install labels where they actually survive.

Mistake #4: You Pull Labor Off Value-Creating Work

Every hour your team spends installing labels is an hour they’re not:

- Picking

- Shipping

- Receiving

- Managing inventory

- Supporting go-live activities

During WMS implementations, expansions, or peak season, that tradeoff is brutal.

Self-install feels cheaper, until you account for:

- Overtime

- Missed throughput

- Delayed go-lives

- Supervisor distraction

Professional installation compresses timelines and keeps your operation focused on what matters most.

Mistake #5: No One Owns Final Validation

This is the quiet killer.

In self-installed projects:

- No one checks every label

- No one scans every barcode

- No one validates numbering logic aisle-to-aisle

Everyone assumes someone else verified it.

Professional installation includes:

- Post-install audits

- Scan validation

- Placement verification

- Issue resolution before go-live

That final inspection step prevents small errors from becoming permanent problems.

Rack Labeling Is a One-Time Chance to Get It Right

Once racks are full, fixing labeling mistakes becomes exponentially harder.

You’re now:

- Working around inventory

- Replacing labels piecemeal

- Introducing inconsistency

- Training people on workarounds

A bad install doesn’t just slow today’s operation—it limits tomorrow’s scalability.

Why Professional Installation Actually Costs Less

Here’s the counterintuitive truth:

Professional rack label installation usually costs less than DIY, when measured correctly.

Why?

- Faster installs

- Fewer reprints

- No rework

- No downtime

- No operational drag

You’re not paying for labor.

You’re paying for certainty.

How Pacific Barcode Approaches Rack Label Installation

At Pacific Barcode Inc., our Warehouse Division treats installation as a mission-critical phase, not an afterthought.

Our process includes:

- Pre-install planning and layout validation

- Consistent placement standards

- Environment-matched materials and adhesives

- Professional crews trained for live warehouses

- Final scan and visual validation

We don’t just install labels.

We protect the integrity of your warehouse system.

Final Thought

Installing your own rack labels feels like control.

In reality, it introduces:

- Variability

- Risk

- Rework

- Long-term inefficiency

Rack labeling is foundational infrastructure.

It deserves the same discipline as racking, WMS, and automation.

Do it once.

Do it right.

And let your team focus on running the warehouse—not fixing it.