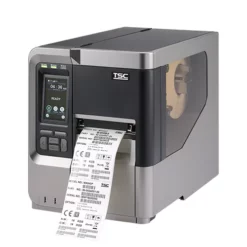

Pacific Barcode presents a diverse selection of industrial color thermal printers, designed to meet all your barcode and label printing needs. Our inventory includes a variety of printers that cater to different business requirements, from small-scale operations to large industrial applications. These printers are known for their durability, efficiency, and high-quality printing capabilities, making them ideal for a range of uses including retail labeling, product identification, and barcode generation. Whether you require a basic model for simple tasks or a more advanced printer for complex printing jobs, Pacific Barcode has the right solution for you.