Warehouse Signs, Labels & Installations

We manufacture, we install, and we support your operation with printers, inks, spares, and mobile workstations.

Get a Quote Shop Warehouse Labels

We manufacture, we install, and we support your operation with printers, inks, spares, and mobile workstations.

Get a Quote Shop Warehouse LabelsIn-house manufacturing, professional installation, and tight project management, done by one team. Our product lineup includes:

Repositionable, barcode-ready labels that snap to metal racking for fast re-slotting without adhesive mess—perfect for seasonal resets, cold storage and 3PL’s

High-contrast beam labels with human-readable text and barcodes, sized and coded to your WMS schema.

Vertical, color-coded level markers on uprights that cut wrong-level picks and speed up training in high-bay aisles.

Large, readable aisle numbered and/or lettered IDs that help your warehouse staff quickly and efficiently locate the correct picking or receiving aisle or dock doors.

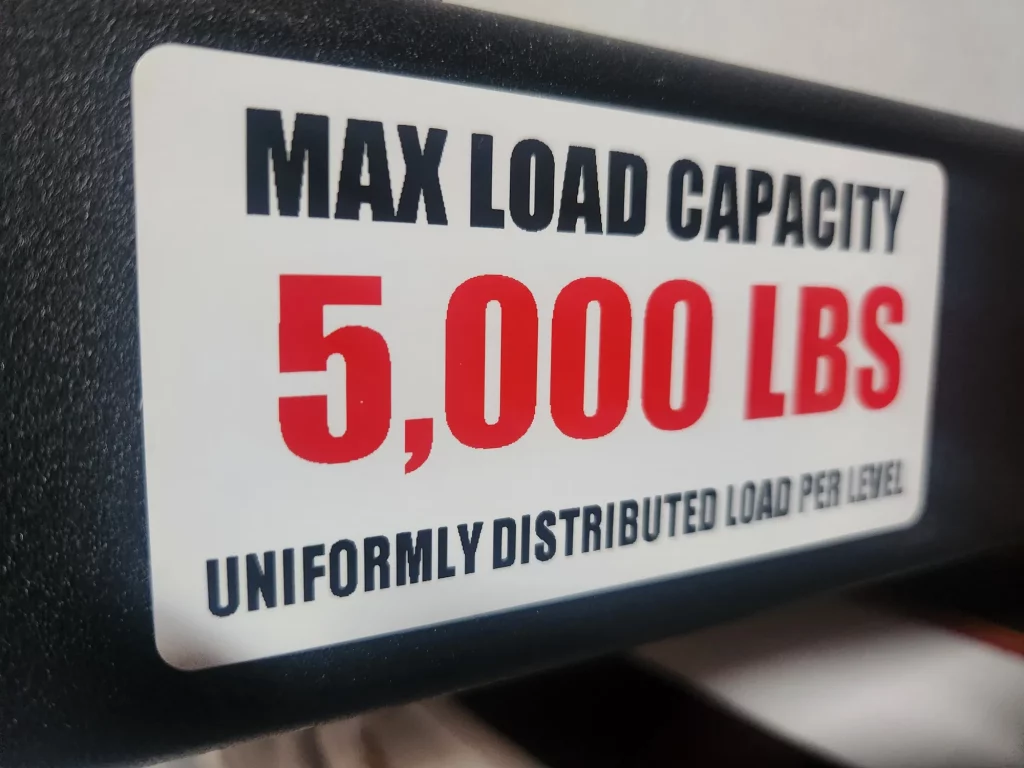

Clear, durable weight-limit labels for beams and bays to prevent overloading and pass safety inspections with confidence.

High-visibility “KEEP CLEAR” markers that support high-pile fire code compliance and faster sprinkler activation. Mandatory is several states including California.

Overhead or conduit or cable-mounted signs for bulk and floor storage that scan from distance and keep flow moving. Numbering, zone colors, and barcode formats tailored to your map.

Long-range scannable labels that bounce light back to the reader for reliable picks from the floor. Perfect for high-bay racking, fast movers, and forklift-first operations.

Check out our latest catalog to learn more about our warehouse products and services.

Pacific Barcode has a proven methodology for the successful installation of racking labels, warehouse labels, and warehouse signs. Our implementation process has been refined over decades through the experience gained from hundreds of large-scale warehouse projects. We handle every detail of labeling and signage installation so your team can stay focused on running operations smoothly.

Pacific Barcode is a true end-to-end manufacturing company. We design, produce, and manage every aspect of our warehouse labels and warehouse signs, ensuring complete control over quality and consistency. Our installation services are fully managed by professional on-site supervisors and supported by our dedicated Project Management team. By leveraging more than 22 years of experience, we ensure your project is executed with precision, helping you improve efficiency, reduce operating costs, and rely on experts who understand warehouse labeling from the ground up.

Our collective team will meet to review the project details including:

• Go live dates.

• Project team members with roles and responsibilities.

• Validate project details.

• Schedule weekly cadence discussions.

• We will collectively review the full details of the project.

• The Pacific Barcode Project Manager will run through the timelines and deliverables.

• Project tasks will get assigned to both teams.

• Cadence meetings will be established at an agreed upon frequency.

• These meetings will serve as a check point to validate deliverables and tasks by both parties.

• Any risks will be identified and dealt with.

• Any necessary course corrections will be discussed and agreed upon.

• Several days prior to the first day of installation, a meeting of the stakeholders will be held in order to validate that all necessary deliverables have been met and are on track.

• A second risk assessment is performed to identify any additional course corrections to be discussed and agreed upon.

• This is a part of the Cadence Meeting step.

• These meetings are leveraged to validate that the installation is on track.

• Any issues will be handled and dealt with accordingly.

• This meeting /discussion will serve to handle any remaining installation items.

• We will share any lessons learned and improvements with both parties.

With over 22 years of experience, Pacific Barcode is one of the few companies that both manufactures and installs complete warehouse labeling and signage systems. Our in-house production ensures every label meets your exact specifications, while our certified installation crews deliver professional, on-time execution in facilities of any size. From planning and layout through final inspection, we own every step—so your project is done right the first time.

We stand behind the quality of our products and only provide the highest quality materials.

We ask a lot of questions because there may be things you simple didn’t know that you didn’t know, and our team will provide guidance and advice.

We have over 22 years of experience manufacturing and installing warehouse labels and signs.

We are an end-to-end label and sign manufacturing organization which means that we own the process from start to finish.

You can download our installation form by clicking the button below, fill it out and send it to sales@pacificbarcode.com

From design to installation, our labeling experts help you create a safer, more efficient, and fully compliant warehouse environment.

Yes — we handle both manufacturing and installation in-house. Our team produces custom warehouse labels and signage at our facility, ensuring precision, durability, and fast turnaround times. Then, our dedicated installation crews manage the entire on-site process — from layout planning and project coordination to installation and final inspection.

We can:

Absolutely. We stage by zone and schedule during low-impact windows to keep throughput moving.

Yes — we specialize in label and signage solutions designed to perform in harsh environments, including cold storage and outdoor areas.

Pacific Barcode, Inc. is certified to ISO 9001:2015 for our quality management system (Perry Johnson Registrars, Inc.). That means consistent materials, controlled processes, and a culture of continuous improvement—so labels look right and scan right, every time.

Quality Policy